August Hauerwas

Manufacturer of Grinding, Lapping, Milling and Turning machines

for all kind of sealing surfaces of valves of DN 8 - 2000 mm

Hauerwas Ventilette

machines for coarse to the finest grinding and lapping of

sealing surfaces of valves with flat or tapered seats of DN 8 - up to DN 200 mm

Characteristics depending of specific model:

- spindle motion:

+ rotation

+ reversing mode

+ eccentric

for best sealing surfaces

- axial spring suspended machine spindel with pressure scale

- infinitely variable speed control

- tool carrier with self-locking coupling snap closure

- ball mandrel as pick up aligns spindle and machining discs to flat sealing surfaces

- machine and complete accessories in box with foam insert, abrasives in clear plastic boxes

- available with electric or compressed air drives in industrial design

- Accessories (e.g. pipe clamp, machine stand, tilting table, ...) for mobile or stationary use available

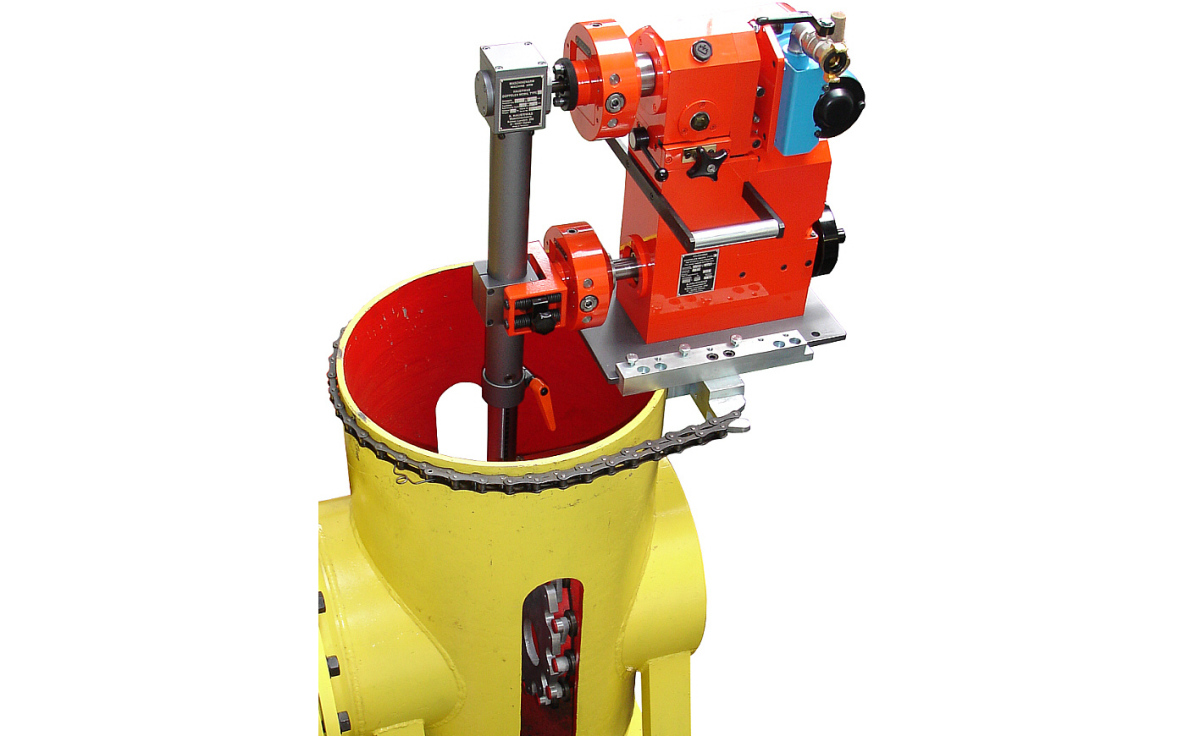

Hauerwas Doppelex Mobil

mobile grinding and lapping machines with synchronuously running double eccentric and telescopic machine arm.

For coarse to finest grinding and lapping of sealing surfaces of slide-valves, wedges and flanges of DN 40 - up to DN 2000 mm

- stable designed for the highest loading under continuous load service

- synchronously running double eccentric for finest surface quality

- telescopic machine arms, no obstacle to repair slide-valves in confined position due to compact sizes

- both sealing surfaces can be repaired without moving machine by rotating the lower part of the machine arms 180°, ideally when working in confined positions.

- machines are working in any installation positions

-between the Doppelex Mobil machines, grinding and lapping accessories are interchangeable

- quick and easy mounting of machine using pipe clamp with chain tensioning

- ball mandrel as pick up of machining discs adapts to angle of sealing surface for easy alignment

- available with electric or compressed air drive in industrial design

which are quick and easily interchangeable

- wheeled transport trolley for storage and transport

- designed for a long life with a minimum of repair

Hauerwas Mobil

mobile grinding and lapping machines for coarse to finest grinding and lapping of sealing surfaces of slide-valves, wedges and flanges of DN 40 - up to DN 800 mm

- solid constructed machine with low weight for highest mobility

- telescopic machine arms:

no obstacle to repair slide-valves in confined position due to compact sizes

- optionally available machining of globe valves: for HM 1, HM 2, HM 1-2, HM 3

- machines are working in any installation positions

- both surfaces can be repaired without moving mounting device by rotating the lower part or the telescopic machine arm or the machine arm by 180°.

- between the Hauerwas machines, grinding and lapping accessories are interchangeable

- quick and easy mounting of machine using pipe clamp with chain tensioning

- ball mandrel as pick up of machining discs adapts to sealing surface for easy alignment

-available with electric or compressed air drive

- wheeled transport box for storage and transport

-designed for a long life with a minimum of repair

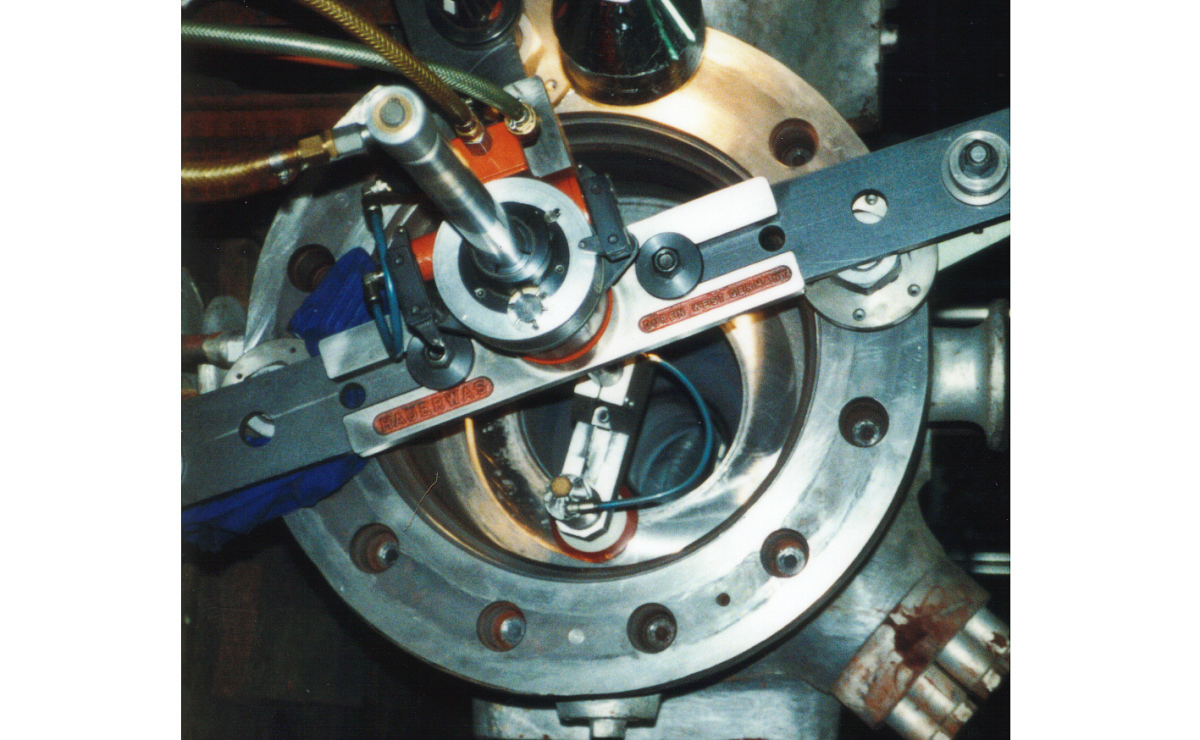

Hauerwas HVS

High - speed mobile valve grinding machine for sealing surfaces

with flat and tapered seats on valves, flanges, compressors, turbines and pumps of DN 30 - up to DN 850 mm

- Machines for face grinding, peripheral grinding, and tapered grinding of sealing surfaces

- CBN or diamond grinding wheels are used for short machining time

- compact supported machine spindle for best working results

- automatic axial feed of 0,001 to 0,004 mm per revolution

- quick manual axial travel for short set-up time

- works in any installation position (horizontal, vertical),

in situ or in a work-shop

- driven by two compressed air motors (5 to 7 bar)

- adjustment device for quick and easy setup available

- wheeled transport box for storage and transport

Hauerwas KPS:

grinding of bolt seats on turbine couplings